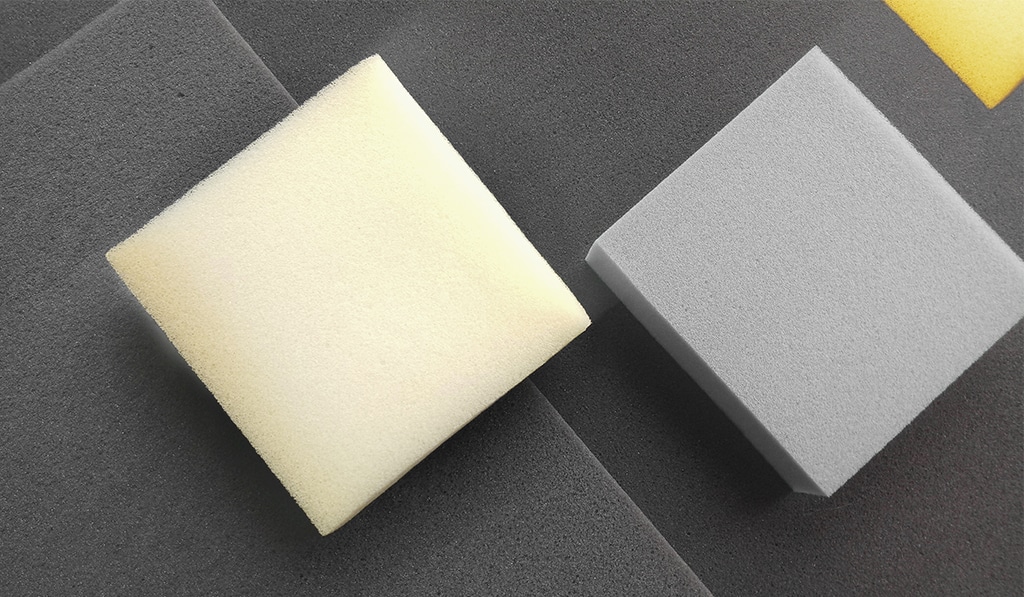

Foam and polyethylene packaging for cargo protection

Protecting cargo during transportation and storage is an important aspect of guaranteeing product integrity and customer satisfaction.

In an increasingly dynamic and globalized logistics scenario, companies need efficient solutions that minimize the risk of damage during each stage.

In this context, polyethylene foams and packaging, especially expanded polyethylene foam (EPE), stand out as a preferred choice for protecting various types of products.

This material is widely used due to its exceptional characteristics of lightness, moisture resistance, impact absorption capacity and versatility.

However, to understand how it adapts to different logistical and industrial needs, it is important to explore the different variants of polyethylene and their respective applications.

Protection and safety with polyethylene packaging

Cargo security in transportation and storage is a priority for any industrial sector.

However, transporting products can be fraught with challenges, especially when it comes to fragile items or those with high added value.

This is where polyethylene packaging comes in, guaranteeing protection against impacts, shocks and even moisture.

The use of polyethylene foams provides an effective layer of protection, absorbing the impact forces that could damage the products.

With their closed cell structure, polyethylene foams prevent moisture from seeping in, preserving the quality of items during transportation.

Its flexibility and adaptability allow it to mold easily to the shape of products, providing customized packaging for each type of load.

Polyethylene foams are excellent at distributing impact forces, minimizing damage to delicate items and ensuring that goods arrive at their destination in perfect condition.

This is an important differentiator for sectors that deal with high-tech products, food, medicines and other sensitive items.

Types of polyethylene foams and their applications

Expanded polyethylene is one of the most common forms of this material and is widely used due to its ability to offer high-quality protection.

There are different types of polyethylene foam, each with specific characteristics to meet different needs.

Polyethylene foam: impact absorption and resistance

Polyethylene foam is known for its excellent ability to absorb impacts. The structure of the material, made up of closed cells, guarantees efficient absorption of external forces.

This makes it ideal for protecting products during transportation and storage, especially when these products are susceptible to damage from sudden impacts.

Polyethylene foam's resistance to different environmental conditions, such as variations in temperature and humidity, also contributes to its effectiveness in preserving products.

This type of packaging offers an effective solution for heavy items, such as industrial equipment, which need robust impact protection.

Polyethylene foam is able to provide effective cushioning without compromising the integrity of the load.

Expanded Polyethylene Foam (EPE): maximum protection for sensitive products

When it comes to protecting sensitive products such as electronics, precision instruments or automotive components, expanded polyethylene foam (EPE) stands out as one of the best options.

EPE is a more advanced version of polyethylene foam, offering superior protection due to its higher density and closed-cell structure.

This material offers a very effective layer of protection, ensuring that products are safe during transportation, even in shock or impact situations.

EPE is highly resistant to moisture, which helps protect products from possible damage caused by adverse environmental conditions such as rain or temperature variations.

Its closed-cell structure also prevents the foam from absorbing liquids, keeping items protected during transportation.

EPE foam: lightness and versatility for different applications

One of the great advantages of EPE foam is its lightness, which makes it easier to handle and transport goods.

Unlike other packaging materials, which can be heavy and difficult to work with, EPE foam does not add significant weight to packages. This reduces transportation costs, since the weight of the packaging also has an impact on the total cost of shipping.

The versatility of EPE foam makes it ideal for different types of products. The foam can be molded according to the shape and size of the item, providing customized protection for loads from various segments.

Its flexibility makes it an excellent choice for protecting items of different shapes, such as electronics, glass, automotive parts and much more.

Expanded Polyethylene: versatility and efficiency in load protection

Expanded polyethylene has established itself as one of the most efficient materials for protecting loads, due to its unique characteristics. The versatility of this material is one of the main factors that makes it the preferred choice in many industrial sectors.

Expanded polyethylene is capable of meeting the needs of different industry segments, such as automotive, electronics and logistics in general.

Its efficiency in absorbing impacts and resisting adverse environmental conditions allows loads to be protected effectively, reducing the risk of damage during transportation.

Applications of expanded polyethylene in industry and logistics

Expanded polyethylene is widely used in various industries due to its superior qualities in terms of protection and efficiency.

In the electronics industry, for example, EPE is used to package sensitive devices such as smartphones, computers and televisions, offering an effective layer of protection against impacts and falls.

In the automotive sector, EPE foam is used to package parts and components, ensuring that they arrive at their destination undamaged.

Because it is light and flexible, the material can be easily molded to fit different shapes and sizes, offering maximum protection without taking up too much space.

Applications of polyethylene foam in logistics and industry

Logistics and modern industry demand packaging solutions that are efficient, economical and safe. Due to its exceptional properties, polyethylene foam has been widely adopted as a packaging solution in various sectors.

Protecting electronics and fragile items

One of the sectors that benefits most from the use of polyethylene foam is electronics. Polyethylene foam offers excellent protection for sensitive devices such as computers, smartphones, televisions and other high-tech appliances.

Its ability to absorb impacts and protect against falls makes packaging safer, ensuring that products reach consumers in perfect condition.

EPE foam also helps insulate products from moisture, which is especially important for electronic devices, which can be damaged if exposed to humid environments.

Used in the automotive industry for shock absorption

In the automotive industry, polyethylene foam is widely used to package delicate parts and components such as glass, mirrors and other sensitive components.

The foam helps to absorb impacts that may occur during transportation, preventing damage that could affect the quality of the parts and generate financial losses.

EPE is ideal for protecting irregularly shaped components, guaranteeing customized packaging that maximizes the safety of goods.

Safe packaging for transporting delicate goods

Whether transporting food, pharmaceutical products or other delicate items, polyethylene packaging ensures that goods reach their destination in perfect condition.

Polyethylene foam's ability to withstand impacts, shocks and moisture makes it an ideal choice for transporting sensitive products.

The flexibility and lightness of EPE foam reduces operating costs, offering a cost-effective solution without compromising safety.

Conclusion

As we have seen, polyethylene foams and packaging, especially expanded polyethylene foam, play a fundamental role in protecting cargo during transportation and storage.

Its ability to absorb impacts, resist moisture and adapt to different shapes and sizes of products ensures that items arrive at their destination undamaged.

In addition, the lightness and versatility of EPE foam offer significant economic and logistical benefits, making it a highly effective and sustainable solution for various industries.

Safety and efficiency in cargo transportation are guaranteed with the use of polyethylene foam, which makes it indispensable for any logistics operation.